CASE STUDY:

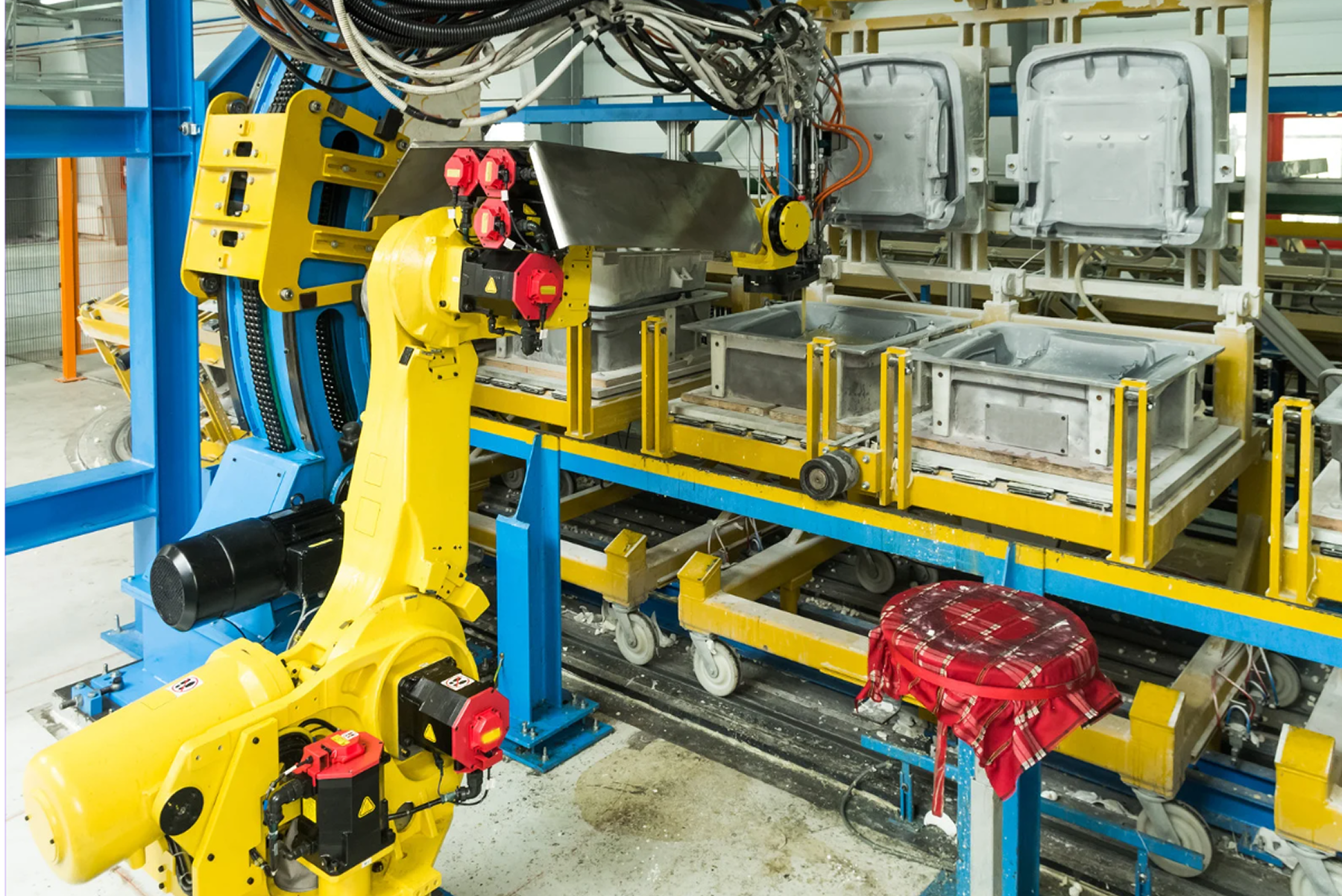

Stop & Go Production Lines for Car Seat Assembly

COMPANY: Car seat manufacturer

INDUSTRY: Automotive

PROBLEM: Need to modernize the production line to improve efficiency, assembly precision, and adapt to new seat models.

CHALLENGE: Automation and modernization of the production line.

To increase efficiency and implement modern technologies, the Client decided on a comprehensive modernization of the production line for car seat assembly. A key element of the project was the implementation of a new electrical standard and PLC controller software using Siemens Simatic S7 with a Proface HMI system. Additionally, the system included a locking and inspection station for the rear seat, which required precise component integration and optimization of the production process.

SCOPE OF WORK: Comprehensive automation implementation

The MJ Group team, in cooperation with AUTOMET Group, carried out a comprehensive implementation that included:

- developing and implementing an electrical standard compliant with the Client’s requirements,

- designing and programming Siemens Simatic S7 PLC controllers and the Proface HMI system,

- full modernization of the control systems for the seat production line,

- integration and optimization of the rear seat locking and inspection station,

- complete commissioning and testing of the production line to ensure maximum efficiency,

- collaboration with the engineering department in France to ensure compliance with international standards.

SOLUTION: Modern industrial automation system

Thanks to the implementation of a new electrical and automation standard, based on Siemens Simatic S7 PLC controllers and the Proface HMI interface, MJ Group provided the Client with:

- increased precision and reliability of the assembly process,

- full control over every stage of production,

- the ability for fast diagnostics and remote system monitoring,

- improved ergonomics and an intuitive interface for production operators.

RESULTS AND BENEFITS FOR THE CLIENT

Thanks to the modernization of the production line, the Client achieved:

- increased production efficiency through reduced downtime and system optimization,

- improved quality and precision of seat assembly in compliance with international standards,

- enhanced workplace safety for operators,

- the ability to quickly adapt the production line to new car seat models,

- reduced operating costs thanks to the use of modern components and software.